About Me

I began my journey in Peru, where I graduated top of my class in Mechanical Engineering from the Universidad Nacional de San Agustín de Arequipa (UNSA).

My academic performance earned me the prestigious Beca Presidente del Perú, a national full scholarship awarded to the country’s top students.

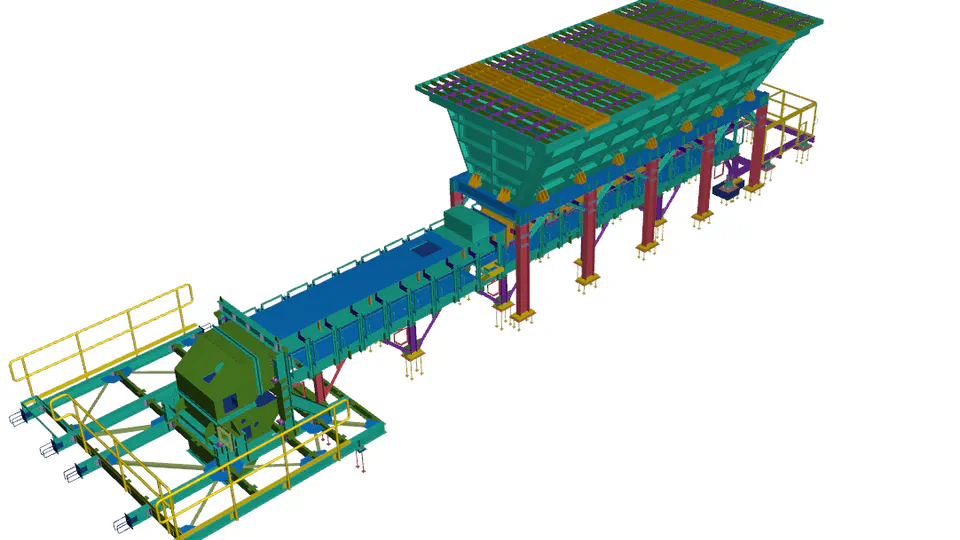

After graduation, I was selected as one of 100 finalists out of 16,000 applicants to join Freeport-McMoRan, where I developed Machine Learning solutions for predictive maintenance (Remaining Useful Life) across global mining operations, combining: data science, reliability engineering, and real-world industrial systems.

Currently, at Bosch Rexroth, I design and orchestrate Docker-based ETL pipelines, real-time monitoring systems, and machine/deep learning models for predictive maintenance of hydraulic systems.

My work bridges industrial automation and AI-driven data architectures, connecting physical assets with scalable, intelligent software systems.

Focus Areas

AI Architectures & Time-Series Intelligence

Development of advanced ML/DL architectures including: LSTM networks with attention CNN-based temporal filters and survival models for Remaining Useful Life (RUL) prediction, anomaly detection, and adaptive retraining in high-frequency industrial data environments.

Expertise in explainable AI using SHAP, PDP, and interpretability frameworks for model transparency and reliability.Scalable Data & ETL Orchestration

Design of modular ETL pipelines and multi-container architectures using Dagster, Apache Airflow, and Docker.

Implementation of real-time dataflows integrating SQL/NoSQL systems (PostgreSQL, Snowflake, InfluxDB) and streaming technologies (Kafka, Solace, MQTT) for industrial telemetry.Industrial Connectivity & Cyber-Physical Systems

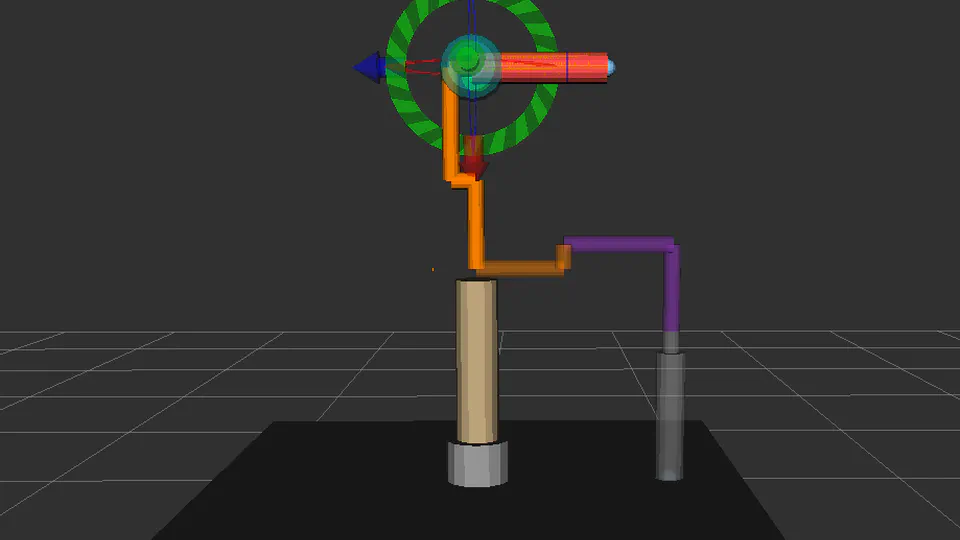

Integration of OPC UA, MQTT, and CtrlX Core communication frameworks for robust data acquisition across hydraulic, robotic, and automation systems.

Bridging control theory, system identification, and AI-based condition monitoring to enable self-diagnostic industrial assets.Cloud, DevOps & Scalable Deployment

End-to-end deployment of ML pipelines using Azure Machine Learning and Databricks, with full CI/CD integration and containerized workflows.

Strong focus on reproducibility, versioned data pipelines, and edge-cloud synchronization for Industrial AI.

I aim to pursue a Ph.D. in Robotics, Control Systems, or Industrial AI, developing impactful technologies that bridge data and physical systems.

- Smart Systems for Industrial Engineering and Robotics

- Technical Software Architecture & Data Automation for Industry 4.0

- Fusion of Data Science with Physical Modeling

M.Sc. Computational Science and Engineering

University Ulm

M.Sc. in Advanced Precision Engineering

Hochschule Furtwangen

Diplom in Machine and deep Learning

Universidad catolica san pablo

B.Sc. in Mechanical Engineering

Universidad Nacional de San Agustin de Arequipa